Information vs. Operational Technology: IT vs. OT Explained

Since the rise of the Internet, organizations and individuals have increasingly sought ways to keep their information secure and private. IT has witnessed a changing cyber threat landscape, and businesses have relied more and more on the Internet and data to function.

However, the attack landscape widened in the 2010s. With widespread computer worms like Stuxnet in 2010, cybercriminals have gained critical access to organizations through operational technology. As businesses increasingly leverage IT and OT to achieve greater efficiency, they are also increasingly vulnerable to attacks.

But what is the difference between IT and OT, and how does that impact cybersecurity?

The short answer, as cyber expert Ronald Beiboer explains: “IT is about information and OT is about operations.” He continues:

- IT exchanges information.

- OT influences actual machines or physical processes like our power grids and the water treatment industry.

“If you look at it this way, the potential impact already sounds scary.” Security, therefore, is paramount.

In this article, let’s unpack the two terms, their differences, and how the changing cybersecurity landscape will impact industrial efficiency and safety.

What is IT?

IT, or information technology, is a general term that covers the total creation, processing, storage, retrieval, and exchange of data. Although it traditionally referred to computers, the term now includes common endpoint devices — tablets, smartphones, IoT devices, and servers — as part of its infrastructure.

Most people think of technical support when they think of IT, but it encompasses much more than that. Just a few of the subsets of IT include:

- Communication

- Software development

- System administration

- Telecommunications

- Networking

- Infrastructure

- Information Security

IT ensures that organizational data is processed, stored, and managed efficiently and safely. It’s closely related to network access, so IT is critical for ensuring all data is secure and risks are identified and mitigated.

(Related reading: IT infrastructure & data management.)

What is OT?

OT, or operational technology, is a term used to cover the monitoring and control of production, particularly in industrial and factory environments. While IT mostly concerns itself with data and the internet, OT is critical for physical hardware. As a result, OT’s primary concern is downtime.

Downtime is planned or unplanned production pauses — and it can be a serious cost for businesses. In fact, across the Global 2000 companies, downtime costs $400 billion per year. Averaging that out, you’re looking at $9,000 per minute of downtime.

This is important information because downtime affects everyone: 76% of organizations had downtime in 2022. And this is a primary focus of OT, preventing as much downtime as possible.

One of the most common ways that OT prevents downtime is by implementing an industrial control system, like SCADA (or Supervisory Control and Data Acquisition). These types of software control programmable logic controls that monitor and control factory machines and production and prevent downtime by turning off machines and sounding alarms in the event of system malfunction.

However, this is increasingly changing as data acquisition becomes more common in OT. Many early OTs, like SCADA, aren’t networked. These closed systems cause data siloes and impact its value.

- Like IT, OT has transformed and expanded over the years to include more technology. It now includes:

- More automation

- Embedded technology

- Monitoring capabilities

With the introduction of new OT networks, organizations can now leverage IoT and edge devices to control devices and manage equipment at the machine and factory levels.

The changes to OT allow platforms to analyze information faster and far more accurately than human operators. Plus, they are configurable to work with user-defined parameters and configurations.

IT vs. OT: What’s the Difference?

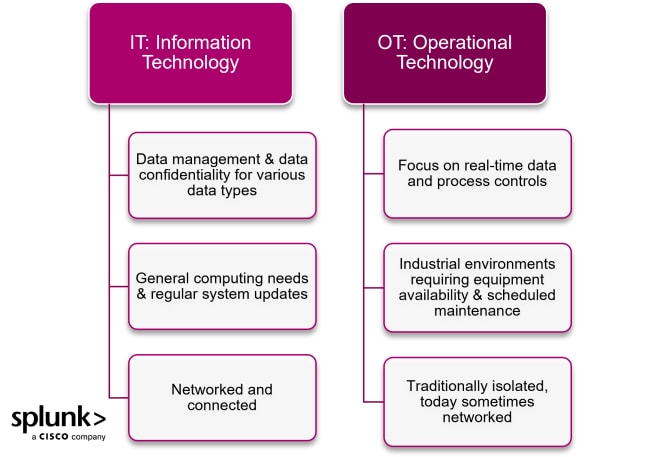

In general, IT manages data, while OT handles machinery and physical operations.

- IT leverages software and small hardware, like computers, phones, and tablets, to collect and store data and assist organizational decision-making.

- OT leverages technology to monitor and control processes and equipment for industries such as manufacturing to ensure they run safely and efficiently.

Another key difference is how IT and OT data are leveraged. IT focuses on meeting broad business needs. For example, it deals with voice communication, transactions, data storage, and other data needs.

However, OT focuses on machine-driven, real-time data for users and leaders. It comes from controlled physical equipment through software and other digital technologies with advanced analytic engines that are dedicated to optimizing industrial processes.

(Related reading: cyber-physical systems.)

IT and OT working together

The relationship between IT and OT is like an electrical grid. IT is the power plant that generates and distributes electricity across vast networks of transmission lines, reaching cities, industries, and homes. OT is the system of transformers, circuit breakers, and switches that manage the flow of electricity at the local level, ensuring it’s delivered safely and at the correct voltage for various devices and applications.

Cybersecurity for IT vs. OT: A blurred line

IT has long been a top security concern for businesses, and most organizations invest significant resources in managing and securing their networks. These investments only increased as many moved their IT functionality to the cloud.

IT and OT were traditionally wholly separate, but the rise of an IT/OT convergence is transforming business. It offers organizations several benefits, but it has some risks.

Benefits of IT/OT convergence

A convergence lowers the chance of encountering downtime with OT, which is an appealing way of reducing costly and headache-inducing disruptions. When the two work together, organizations can better leverage real-time data, providing more actionable insights and better decision-making.

Looking at IT and OT together also improves scalability as IT functionality moves to the cloud and becomes more affordable. OT and IoT use large amounts of data, making cloud-based storage a more cost-efficient system.

Risks of IT/OT convergence

However, some security experts hesitate to converge the two.

One perspective is that OT security risks will become more prevalent, as OT by nature increases and expands the potential attack surface for organizations. Once industrial equipment is connected to data, cyber-attacks on vital infrastructure become a possibility. This can be even more risky for legacy systems that are not equipped with the latest security features and are more vulnerable to cyber-attacks.

Plus, OT and IT teams may be subject to separate security standards that make addressing these threats contentious.

As a result, many organizations choose to keep IT and OT networks separate. However, it can be an issue when OT data has to pass through IT systems to function properly across the organization. As businesses leverage the Industrial Internet of Things (or IIoT) to access deep visibility across organizations, many are learning to work together to create a more efficient and secure business.

Cybersecurity is paramount

As the line between IT and OT continues to blur, many organizations are changing their security to have more layers with many protocols to protect their systems at all levels. A comprehensive cybersecurity strategy will be essential as businesses advance technology to create a new industrial revolution.

See an error or have a suggestion? Please let us know by emailing splunkblogs@cisco.com.

This posting does not necessarily represent Splunk's position, strategies or opinion.

Related Articles

About Splunk

The world’s leading organizations rely on Splunk, a Cisco company, to continuously strengthen digital resilience with our unified security and observability platform, powered by industry-leading AI.

Our customers trust Splunk’s award-winning security and observability solutions to secure and improve the reliability of their complex digital environments, at any scale.