Is it Star Trek or reality?

It uses more than 66,000 computer-controlled devices and has 40,000 optics that guide and amplify 192 laser beams at a target smaller than your thumb — producing temperatures of more than 100 million degrees Celsius and pressures exceeding 100 billion times Earth’s atmosphere. So, Star Trek, right?

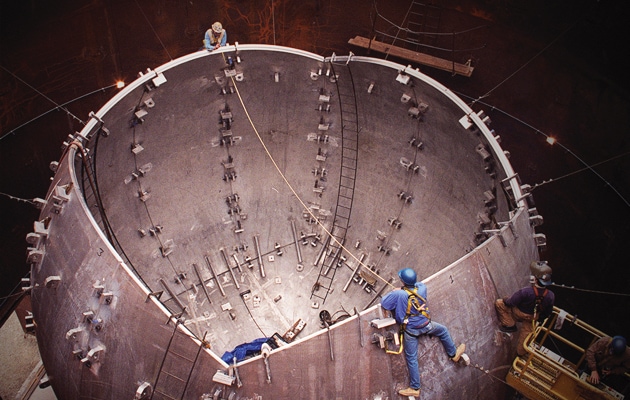

Actually, it’s both. The warp core, featured in Star Trek: Into Darkness, is set in the target bay of the National Ignition Facility (NIF) — the most energetic laser facility ever built.

Warp Core - the NIF Target Bay, which also served as the set for the engine room of the Starship Enterprise in the 2013 film "Star Trek: Into Darkness." NIF’s 192 laser beams converge at the center of this giant sphere to make the tiny hydrogen fuel pellet implode. Credit: Damien Jemison

Just outside a suburb an hour east of San Francisco at the Lawrence Livermore National Lab (LLNL), the National Ignition Facility & Photon Science directorate has been instrumental to advancements in science, including astrophysics, nuclear technology, fusion ignition and optogenetics. The facility is in such high demand for research that scientists sometimes wait years to get their turn at experimenting with the one-of-a-kind laser array.

But it didn’t come easy. From the facility's initial construction to each laser shot, NIF has required a comprehensive approach with new takes on everything from manufacturing to data processing.

Building the facility, which began official operations in 2009 after 12 years of construction, required breakthroughs in optics and manufacturing, such as continuous-pour glass, rapid-growth crystals, innovative optical switches and deformable mirrors. And making the most of the facility and the experiments it runs has required a revolutionary approach to data management, due to its thousands of connected devices.

NIF construction even contributed to archaeology: a 16,000-year-old mammoth fossil was discovered during site excavation.

Data is really critical to our rate of learning and the progress we make on the complex questions we're trying to understand at NIF.

The Nuclear Mission

Funded by the National Nuclear Security Administration (NNSA), NIF’s primary mission as part of the is to enable nuclear research without full-scale testing — replacing controlled nuclear blasts under the Nevada desert with a precision-oriented lab environment in the Northern California suburbs. The NNSA’s goal is to ensure the safety, security and reliability of the United States’ nuclear deterrent capabilities. NIF is crucial in this mission as it is the only facility that can create the conditions needed to understand thermonuclear burn and fusion ignition. It’s a place where humans can observe events that take place in extreme conditions with frequency — and measure them with greater precision — without the old-fashioned blow-it-up-in-the-desert approach.

NIF Target Chamber - a service system lift allows technicians to access the target chamber interior for inspection and maintenance.

NIF is the only facility that can create the conditions required for understanding both the operation of modern nuclear weapons and our cosmos.

In short, NIF provides insights into how different materials react to certain temperatures and pressures, records the results and makes it easy to share with the rest of the scientific community, whether the topic is weapon physics or the makeup of our universe.

The Double Shot Challenge

Due to high demand and expectations, NIF was tasked by the National Nuclear Security Administration (NNSA) in 2014 to double its annual number of laser shots to 400 from 200. NIF needed to be more efficient, tactical and generally deliver more results without adding overhead or resource strain. So it leaned on technology providers and industry best practices to deliver on this mandate.

Conducting more shots per year required retooling and rethinking asset management and maintenance cycle processes, as well as taking a closer look at the heart of NIF’s operations — the purpose-built Integrated Computer Control System (ICCS).

Control Room Countdown - Every aspect of a NIF shot is checked and monitored in NIF’s NASA-style Control Room.

NIF’s ICCS was inspired by NASA’s Mission Control, where operators have telemetry on every component involved in a launch.

The ICCS manages all the components of the NIF facility. This system ensures the 192 laser beams converge on a tiny target that fits within a space equaling half the width of a strand of human hair and maintaining precisely the right energy levels. The process requires more than 2,000 computers executing more than 3.5 million lines of code.

A single malfunctioning component could throw the whole shot off, compromising experiments and wasting resources. The multi-data-source nature of the environment coupled with the need for near-real-time insights requires a robust plan and powerful technology stack. Fortunately, monitoring and diagnosing the complex technology components is possible with the right platform.

With a data-first approach — focusing on modern technology including virtualization and machine learning — NIF reached its goal of 400 shots on-time and without compromising uptime or data integrity.

Shots are conducted, the facility grows in complexity, maintenance has to be precise and security always a focus. NIF is a state-of-the-art facility with operators requiring the most detailed and data-backed insights to ensure experiments go smoothly and yield the most accurate results.

We were doing IoT before IoT was even a thing. We had to build something that could help us really find out what was happening in the facility.

NIF uses Splunk for operations:

Control System Monitoring

Visualizes system performance and monitoring as well as accompanying alerts to highlight atypical host utilization (e.g. framework servers, supervisory applications, front-end processors and operator consoles) and simplify the understanding of events and processes.

Long-Term Trend Monitoring

Without having to structure any data or stopping experiments for inspection, NIF can identify patterns in the capacitors storing energy used during laser shots, and predict when these capacitors will need maintenance.

Gantt Visualizations

From initial setup to laser beam alignment to firing intervals, each shot of the NIF laser is composed of complex sequences. The ability to drill-down into the complexity makes it easy for the NIF team to answer time-sequence questions regarding troubleshooting or performance analysis.

Finding Stragglers

Precision is key to each shot. By setting up a comparative approach to catch outliers in NIF Automatic Alignment, NIF is able to quickly find which laser beams are throttling overall performance through faulty automated alignment processes.

NIF is led by data, by the need to understand what’s actually happening at an atomic-level. This means NIF’s IT team has to keep the infrastructure in perfect order, every time.

Scientists expect that data to be accurate and delivered quickly — it’s used for other experiments and to further their scientific career. As such, we have to ensure that we make decisions with the right data to effectively resolve any issues that could affect the next shot.

NIF’s ability to hit such precise experimental requirements at such a breakneck-pace means the facility is making important contributions to a range of sciences, including two important areas of study: Clean Energy and Cosmic Exploration.

Currently, fusion requires more energy to initiate than is produced by an experiment. Scientists at NIF hope to change this by achieving fusion ignition, where more energy is produced than is required to initiate the reaction. If achieved, fusion ignition in a laboratory setting would be a first for humanity and a step toward boundless clean energy, since fusion is carbon-free.

The opposite of fission (employed in today’s nuclear power plants and involving the splitting of heavy atoms), fusion uses lasers to combine two hydrogen isotopes, deuterium and tritium, into a helium nucleus, the byproduct of which is tremendous energy.

Understanding Our Universe

Fusion reactions echo how stars are born, and why they continue to burn for millions or billions of years. NIF is making astronomy an experimental science with a focus on a star’s life cycle, the creation of elements and the nature of plasma (the most common state of observable matter in the universe). Astronomical observations can be better interpreted, and models can be refined as scientists directly observe the temperatures, pressures and densities found at the core of stars and giant planets. Physical processes detected light years away can be mimicked and studied at a smaller scale and in a controlled lab environment.

More Laser Shots = More Data = Better Science

The right approach to data analytics also opens the door to improvements. Comparing the historical data with new information from experiments helps NIF run better as a facility and gives scientists the opportunity to better understand, and improve on, their experiments.

"Having that transparency into the behavior of experiments reveals patterns that allow us to adapt and change parameters that would have gone unnoticed,” says Dr. Bruno Von Wonterghem, operations manager at National Ignition Facility. “It’s critical to our rate of learning and making progress on the complex questions we’re trying to tackle every day."

We are trying to achieve fusion ignition at NIF. It has never been achieved and can’t be done in any other experimental facility since they can’t reach the energy ranges and intensity levels we can. It’s the Grand Challenge we have at the lab.

When dealing with incredibly sensitive and high-profile topics including nuclear stewardship and fusion ignition research, validated and repeatable results are critical. Everyone at the NIF facility, from the system architects to the lab directors, wants to make a lasting positive impact on humanity.

It’s not quite Star Trek, but it’s a hell of a start.